Covering the entire value chain from design, artwork, repro and printing plate production

Products, services and technology

Reproflex Scandinavia additionally offers specific services and technology concepts within supply chain setup and flexo printing solutions.

Artwork

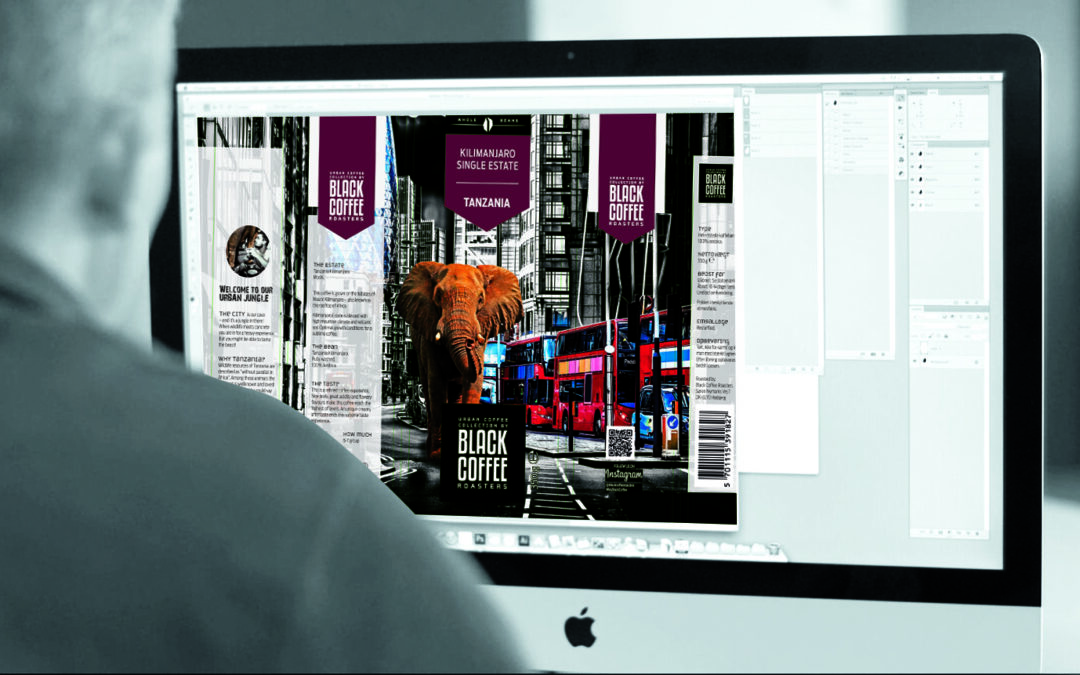

Design

Our graphic designers do their utmost to ensure that your product is head and shoulders above the rest and ensure its success in the store. We take your existing design manual as our point of departure. Involving us in the design phase will ensure that your costs are held as low as possible and you will not be presented with a proposal which cannot be printed using flexo print. After a layout is approved by the customer, our Prepress team takes over completion of the assignment, including trapping and final adjustment to Flexo plate production.

Line and Brand extension

A line extension is a product that incorporates a slight twist on an established brand. This could be converting an ice cream package containing 4 ice creams to a package with 8 ice creams. Line extensions typically include new barcodes, changes in the ingredients and new images in the design.

Brand Extension is when a new product is launched under the existing brand name. E.g. Starbucks is most famous for their coffee products but if they introduce ice cream it will then be a brand extension. We have the capabilities to extend lines for brand owners or for the flexible packaging manufacturers.

Dummies

If you are in the development phase and need dummies for proofing or presentations, Reproflex can produce these on the same substrate as the real packaging.

Prepress

Prepress

Prepress is the process of preparing the artwork for print. This includes trapping, color corrections, step & repeat, distortion, ripping of files for flexo plate production and much more. All parts in the process are important to optimize the final packaging and the graphic artist is taking care of all details and is in contact with the client about the solution.

All jobs are produced in ArtPro application, with help from advanced Esko workflow. For approval of packaging design we use WebCenter as an online approval tool.

Colourmanagement

The profile test will use 4 plates for CMYK print and 7 plates for EGP print. To be able to achieve repeatable results during production runs, the fingerprint must be run under normal conditions – at production speed, using virgin ink and clean anilox rollers. The printed profile is measured with GMG OpenColor software, and this profile is used to handle the color management when working with the prepress. The profile is also used when we make the color corrections of images.

Proof

We will NOT proof you wrong – but with a perfect result each time – on your own substrate! Reproflex has a large selection of proofing systems. Therefore, we are sure to meet your exact needs regading any proof.

All our proofs are made with profiles so quality and colours are garanteed every time. Proofs on certain substrates and with different varnishes, metal colours or extended gamut, can also be done.

3D Packshots

We can produce 3D pack shots of your packagings, creating a visualization of how a final product will look like. This can be made for early presentation/marketing material or as a final product stored in a database for later marketing material. A 3D visualization also shows any weaknesses in the packaging design, especially regarding wrinkles that makes the packaging hard to read or bends the barcode. We also have the capability to add air or fluid to the flexible packaging which gives a more realistic representation of the final packaging.

Extended GAMUT Printing

Extended Gamut is printing with more than the usual 4 color CMYK. By adding Orange, Green and Violet (OGV) you increase the overall range of colors and achieve a more effective production. OGV is used instead of switching between many different special colors.

By using Extended Gamut, you achieve:

- Bigger gamut · Matching of 90% of the Pantone colors

- Save time in the press

- Save money when using less special colors

- Less material used at startup

- Print several jobs on the same plate

DIGIMARC

Value across for both Retailers and Brands.

SUPPLY CHAIN

Deliver more redundant and reliable Data Matrix data for enabled inspection systems.

Business Benefits:

• Improved part matching & waste reduction

• Improved asset management

STORE OPERATIONS

Easily scan for UPC barcode information on enabled barcode scanners.

Business Benefits:

• Improved cashier productivity & wellness

• Accurate and efficient retail inventory data capture

PRODUCT EXPERIENCE

Provide a dynamically updateable QR code replacement for enabled apps.

Business Benefits:

• Product details, marketing campaigns (TV/Audio) & accessibility (hearing impaired, etc.)

• Transparency initiatives like SmartLabel®

Digimarc Barcode incorporates data from both the product code and 2D manufacturing code throughout the artwork to make the design easily identifiable to inspection systems, barcode scanners and mobile devices.

Printing plates

Lams layer plates

We produce Dupont, Asahi and Flint plates in heights from 0.76 to 5.51. We also use Flint Flat Top Dot plates and Dupont Easy plates.

We are Full HD and Flint Flexo Expert certified.

Plates are exposed and processed on the newest equipment technology.

By using lams layer plates, you can achieve:

- Round or Flat Top Dots.

- Pixel+ and Full HD Quality.

- The newest Crystal technology from Esko.

- Cost effective printing plates.

Kodak NX

Kodak Flexcel NX is our premium product and we produce in height from 0.76 to 1.7 mm. Kodak uses flat top structure and advanced DigiCap technology to give high contrast and densities besides sharp edge negative/positive texts. We can use SoftTone+ screening to create smooth highlight in vignettes, graduations to 0 and to add more contrast to the print.

Kodak Flexcel NX digital Flexographic system is used and the plates are exposed on a TIL media which is laminated to the plate. The equipment has a high output, which is needed to produce large amount of plates in a short time. We have produced Kodak Flexcel NX plates since 2008, so we have a lot of knowledge in this area.

By using Flexcel NX plates, you achieve:

- Flat top Dot Structure with advanced Digicap

- SoftTone+ Screening for soft fadeout

- UltraWhite for high opacity in white ink

- High contrast and smooth ink laydown

- A premium product for flexible packaging and label printing

Thermal plates

We produce Thermal plates from Dupont in 1.14 and 1.7 mm. We use the Dupont Fast technology and ensuring us to make print ready plate in less than one hour. We use the Dupont Easy plate which is the newest technology of plate types for Thermal processing. This process of Thermal plates is a safer and more environment friendly process compared to solvent platemaking.

By using Thermal plates, you achieve:

- Fast production of plates to secure minimum downtime on press

- Newest technology of Flat Top Dot plates available

- Low emission production of the plate

- Available for Flexible packaging and label printing

Sleeves

Reproflex has extensive experience in producing and supplying different types of sleeves. Whether it is thin, classic or build up sleeves for Narrow or Wide web customers. This also includes plate mounting sleeves, and combi sleeves with plates.

Sleeves can exclusively be produced with the newest Crystal technology from Esko.

Plate cutting

As a part of the production of printing plates, we can optimize the mounting and printing process by cutting the plates so they fit to the cylinder. We can cut the plates in different shapes to reduce bounce effect on the press as the gap between the start and finish can be minimal. It also gives the advantage of easier and more safe demounting of the plates, as the shape decided can avoid sharp edges which typically results in damaged plates when demounting.

Corrugated mounting

For corrugated jobs, we also mount the plates on mylar, so it fits directly in the printing press. The mounting of plates for corrugated are made based on high mounting standards and procedures, and being able to adopt specific customer requirements. The manufacturing process can be handled in less than a day and with the use of express delivery, we can deliver the mounted plates very fast.

Services and concepts

WebCenter

WebCenter helps you manage and automate approval cycles securely, supported by a fast and accurate online viewing tool.

The collaboration tools in WebCenter help streamline communication between all partners in the packaging and printing supply chains. Work virtually or real-time with your internal creative, marketing and package design. WebCenter keeps everyone on the same page by providing easy-to-use viewing and annotation tools.

By using WebCenter, you achieve:

- Approval are tracked and e-mails are automatically sent to all people involved in the project

- WebCenter helps managing and automate approval cycles securely · The viewer allows users to measure ink details and dimensions · You can track the document history and give approvals · Compare different versions of same design

WebFlex

WebFlex hosting is a service we supply to our customers. WebFlex hosting allows you to view produced jobs through a web browser from a Mac or PC. We ensure that your job is available on WebFlex as soon as it has been produced.

You can access your data 24 hours a day, use the many search options, preview several file formats, carry out image conversion, download and upload files and access many other functions.

By using WebFlex, you achieve:

- WebFlex gives you a general view of all your jobs being produced

- Always newest version of the design available

- Files will be in PDF format, but it is also possible to use other file formats · All data are stored on our server and replicated to another host regularly

Remote proofing

Remote proofing is a technology to secure fast and reliable delivery of proof with controlled color management. Getting exactly the same print results, regardless of whether the printer is in the room next door or in another country, is no problem with our Remote Proofing solution. We have installed several solution for international as well as local clients to optimize the approval process of packaging designs.

By using Remote Proofing, you achieve:

- Fast delivery of proof controlled by advanced color management technology

- GMG OpenColor standard are used to secure predictable results

- You only need to change ink and paper, we controle all other technical issues

- Last minutes changes are possible and still reach the deadline for printing

- No cost for shipping proof

Digital automation

Digital Automation

Automation is here to stay, and we are constantly working to improve this process to achieve the best solution for our digital customers. With Digital Automation by Reproflex, you get your own digital graphic designer who checks and completes your job.All jobs are made using our servers and software, which with the help of our many years of know-how are tailored to your production and customers. This means no investments in expensive servers and software for you.